Neodymium magnets

Pot magnets

Magnetic products

Ferrite magnets

Accessories for magnets

Special categories of magnets

Frequently asked questions about magnets

Neodymium magnets, which we sell in our e-shop, are the strongest type of permanent magnets in the world. They are 10 times stronger than standard black ferrite magnets For example, a neodymium magnet in the shape of a 1x1x1 centimetre cube can hold up to 5 kg. A stronger magnetic field can only be produced by electromagnets. Neodymium magnets are so strong that they are able to demagnetise other types of magnets in the immediate vicinity of them. For this reason, we do not recommend that you place them in the vicinity of Alnico, SmCo, ferrite and other types of magnets.

The most strongly attracted materials are the so-called ferromagnetic materials, which are mainly the metals iron, nickel and cobalt. All alloys of these metals are also strongly magnetic. For example, steel containing iron. Other materials that do not contain these metals also respond to the magnetic field. However, the force applied to them is usually not enough to overcome gravity or friction. This is why brass, for example, does not appear to be magnetic. However, if we limit friction, we can observe magnetism. This phenomenon is very nicely illustrated in this video.

Interestingly, there are also materials that are repelled by magnets. A typical example is graphite, which is repelled so strongly that it can levitate above a neodymium magnet:

A “magnetic strength” is listed for each of our magnets. Technically this is called the pull-off force and is the force by which a magnet is attracted to a thick steel plate. It is often expressed in Newtons (N) and can be converted to kilograms using the following simplified equation: 10 N = 1 kg. The force between the magnet and the steel is the same as the force between two magnets when they are in contact with each other. When choosing the right magnet, it is important to bear in mind that the magnetic force may be reduced if the material is different from steel (e.g. an alloy where magnetic metal is mixed with non-magnetic materials), if the material is too thin (it should be at least 3 mm), if the magnet does not touch the attracted object with its entire surface or if there is a gap between them (e.g. a coloured coating on steel). The magnetic force decreases sharply with increasing distance from the magnet. It usually takes much less force to move a magnet sideways than to pull it away from a metal surface.

The strength shown for each magnet is measured under ideal laboratory conditions and a large margin should be allowed for your purposes. For example, if you need to hold a 50 g magnet to the fridge, we recommend a magnet with a strength of around 500 g.

We calculate the strength with our magnetic calculator. Other suppliers of magnets may use different methods to calculate strength. If the same magnet is stronger or weaker in another store, this is due to a different calculation and not necessarily a difference in quality. Our calculation will usually give a lower strength than that shown in competing shops. You can compare magnets by entering the dimensions and material into our calculator.

Under ideal conditions, the strength is accurate, but realistically you have to allow for a large margin. The strength may decrease if the object is not pure steel, has a layer of other material on it (such as paint), has an uneven/curved surface, the magnet is pulled at an angle to the contact surface (not exactly in the magnetisation direction), the surface of the object is partially rusted or steel thickness is not sufficient. We recommend choosing magnets with a higher pull-off force and before buying a larger quantity of magnets, test them under more difficult conditions.

You can specify the poles in one of the following ways:

- Use the magnetic pole identifier. It’s a handy little tool with a built-in magnet that can rotate freely and adjust its position according to the magnetic field around it. This allows it to determine the north or south pole of your magnet.

- Use another magnet of which you already know which pole is the north pole. The same magnetic poles repel and the opposite poles attract. For example, if one pole of an unmarked magnet is attracted to the north pole of a marked magnet, then it is a south pole.

- If you have a compass, the needle (which normally points north) will be attracted to the south pole of the magnet. Be careful not to place the compass too close to the magnet, as the magnet may damage it.

- If you have at least two magnets, you can put a piece of thread between the two magnets and let them hang down. They will naturally rotate so that the north pole of the magnets is facing north. You can then use the marked magnets instead of a compass to find the points of the compass.

- You can place the magnet on a piece of polystyrene (or other floating object) and place it on the surface of the water. Similar to point 3, they turn the north pole to the north.

No, on all our magnets both poles are equally strong.

No, every magnet must have both a north and a south pole. If you break a magnet in half, you get two separate magnets with a south and a north pole. It is not possible to produce magnets with a single pole.

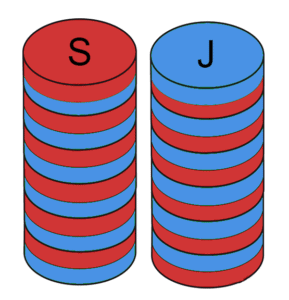

Yes, multiple magnets stacked on top of each other behave the same as one large magnet. For example, if you connect 5 magnets in the shape of a 10x10x2 mm block, they will have the same strength as one 10x10x10 mm magnet.

Separating magnets by simply pulling them apart in the direction of their magnetic force can be very challenging. It is much easier to push them aside and the magnets will repel themselves. Smaller magnets can be separated by hand, but we recommend separating larger magnets on the edge of a table or using a special tool to separate strong magnets. For more information, refer to the article “How to Separate Strong Magnets.”

Neodymium magnets are brittle, so don’t let their metallic appearance fool you. Once you have separated the magnets, keep them away from each other to avoid collision and shattering.

We recommend using adhesive tape, with thicker foam tape being the most effective option. Another option is to pour liquid wax on the magnet, wait for it to harden and remove it with sawdust.

There are no special rules for mailing permanent magnets at Slovak Post and Czech Post. The Slovak Post’s terms and conditions state that the packaging of a shipment should be “appropriate to the nature and weight of its contents, as well as to the method of collection, distribution and time of transport”.

As long as the magnets are properly packaged, there should be no problem shipping them within Slovakia and the Czech Republic. Strong magnets must be wrapped with a layer of polystyrene or other material that increases the distance between the magnets and the surface of the package. The external magnetic field can also be limited by a suitable arrangement of the magnets. If rows of magnets with their north poles on opposite sides of the package are alternated (see picture on the right), their magnetic fields will cancel each other out.

Shipping magnets abroad is more difficult because they can interfere with the measuring equipment in the aircraft. There are much stricter rules for shipping strong magnets by air, and some countries ban magnets from international mail entirely. If you are planning to mail magnets outside of Europe, you can obtain information from the Slovak Postal Service or the Customs Administration.

There are no known adverse effects on human health. Some people believe that placing a part of the body in the magnetic field of a permanent magnet can have a beneficial effect on a person’s health. Again, these claims have not been scientifically proven.

Magnets cannot erase data on USB sticks, memory cards, CDs or DVDs. They should also not erase data from mobile phones or cameras, although they may affect other parts of these devices, such as the built-in compass. Magnets can damage payment and other magnetic cards (e.g. for building access), computer hard drives (only very strong magnets near the hard drive), old CRT monitors, or temporarily slow down a mechanical watch. They can also interfere with the operation of pacemakers and defibrillators. Those wearing these should avoid using strong magnets.

An electromagnet creates a magnetic field using an electric current, usually through a coil (solenoid). The ends of the coil then form north and south poles. However, as soon as we stop the current, the magnetic field disappears. Electromagnets need electricity to work.

Permanent magnets are what most people think of when they hear the word “magnet”. Ferrites, NdFeB, SmCo, AlNiCo and other types of magnets fall into this category. All the magnets found on your fridge, board, speakers, headphones, hard drives, compasses, furniture and mobile phone cases are permanent magnets. Permanent magnets do not lose their strength under normal circumstances, and they always create a magnetic field around them.

The advantage of permanent magnets is that they create a magnetic field without consuming the electricity needed to operate the electromagnet.

On the other hand, electromagnets can be turned on and off as needed and can produce a much stronger magnetic field than permanent magnets.

If you need to sort metal contaminants from a mixture of non-magnetic and magnetic materials, you can use any strong neodymium magnet, for example a 50x50x25 mm block. You can also stack several of these magnets next to each other and place them above the conveyor belt with a mixture of magnetic and non-magnetic materials.

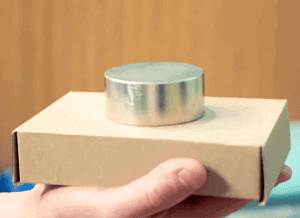

In the picture you can see a similar magnet that collects small pieces of metal:

Magnetic sweepers can also be used for the collection of metal swarf from a flat surface.

If you are looking for a more advanced solution, we recommend MAGSY magnetic separators. You will find their range of magnetic separators on this page, many of which are in stock.

They are named after the chemical element neodymium (proton number 60). Neodymium magnets however, in addition to neodymium, they contain two other chemical elements: iron and boron. The chemical formula of this compound is Nd2Fe14B. Only 1/17th of the atoms in neodymium magnets are neodymium atoms, with iron accounting for up to 72% of their weight and being the main element responsible for their strong magnetic properties.

The letter N indicates that it is a neodymium magnet and the numbers 35 to 52 represent the so-called “maximum energy product”. This is a number that expresses how much the material can be magnetised in MGOe units. For example, the maximum energy product of the N40 material is 40 MGOe. The higher the number, the stronger the magnet. The strength of the magnet is almost directly proportional to this number, so the N55 is almost 60% stronger than the N35. The majority of our magnets are N38 to N45 as this is the range that offers the best strength to price ratio. Material N48 and above is suitable for applications where an extra strong magnet is required, but where space is limited and the magnet must be as small/light as possible, e.g. in electronics.

In the majority of cases, a nickel surface treatment is suitable (in fact, it can be up to three layers: nickel, copper and nickel again). Nickel has fairly good corrosion and scratch resistance. It is also the cheapest of the options available. However, it is not water resistant. It does not protect the magnet as well as a rubber or plastic surface.

Read more about the advantages and disadvantages of different types of surface treatment in this article.

We do not recommend mechanical processing of neodymium magnets for the following reasons:

- The NdFeB material is extremely hard and cannot be machined with conventional tools.

- Mechanical machining generates high temperatures due to friction. When heated above 80 °C, most neodymium magnets lose some of their strength forever.

- If the surface treatment of the magnet is disturbed, the NdFeB material is exposed. This compound oxidises when exposed to air and the magnet gradually loses its strength.

We offer magnets in various shapes and sizes for sale. Please check the main page for a list of categories. If you can’t find a suitable magnet in our range, we also provide custom magnets.

Standard neodymium magnets available from in e-shop can withstand temperatures up to 80 °C. When heated above this temperature, they begin to lose their magnetic power irreversibly. At 310 °C they lose 100% of their strength.

Low temperatures down to -150 °C do not cause a loss of strength in neodymium magnets. On the other hand, magnets are slightly stronger in cold environments.

If the magnets will be exposed to high temperatures, you may want to consider ferrite magnets or explore our category of magnets with high-temperature resistance.

Any strong metal adhesive should do the job. A very commonly used type of glue are two-component epoxy glues. We recommend cleaning the magnet’s surface of dirt and grease and roughening it with fine sandpaper before application. In our e-shop, we offer adhesives such as UHU Plus Endfest and UHU Max Repair, which we have tested on our magnets with good results.

For smaller magnets, double-sided tape works well. In our e-shop you can also buy magnets with sticker.

We do not recommend using a hot glue gun, as neodymium magnets lose some of their strength at high temperatures.

Neodymium magnets are brittle and can break under heavy impact. To prevent breakage, they are often housed in a steel pot for added protection against shocks. In our e-shop, we offer a variety of pot magnets designed for this purpose.

For information on the safety risks associated with strong magnets and instructions on how to handle them safely, please refer to this article.

Most magnets in the orodian.com e-shop are magnetised in this way:

Discs and rings: The poles are located on the flat sides (axial magnetization).

Blocks: The poles are on the walls with the highest surface area (vertical magnetization).

Our pot magnets have the north pole on the active side, while the steel discs represents the south pole on these magnets.

Yes. You can request a quote on the Custom-made magnets page. Before submitting the form, we recommend you browse our range of neodymium, ferrite and pot magnets. We have a wide range of different products in stock and customisation is not usually necessary.

Orders placed before 12:00 pm. Monday-Friday will be delivered by courier the next business day. Other orders will be delivered within two working days. Orders placed over the weekend will be processed on Monday and delivered on Tuesday.

If you choose to pay by bank transfer, we will process your order once we have received your payment, which will usually delay delivery by one day. You can speed up the processing of your order by sending us a payment confirmation (a screenshot is sufficient) from your internet banking to info@orodian.com.

If you need magnets urgently, call us on +421 46 202 1200 and in some cases we can deliver late orders the same day or arrange Saturday delivery.

We’ll email you to let you know when your order leaves the warehouse. The package will usually be delivered on the next working day after it is sent.

If your order takes longer than two working days, please contact us.

We are able to offer favourable wholesale prices to both VAT payers and non VAT payers. We supply magnets to companies for production and further retail sale. Contact us at info@orodian.com and we will provide you with a personalised quote.

If we do not have the required quantity of magnets in stock, we will do our best to supply them as quickly as possible.