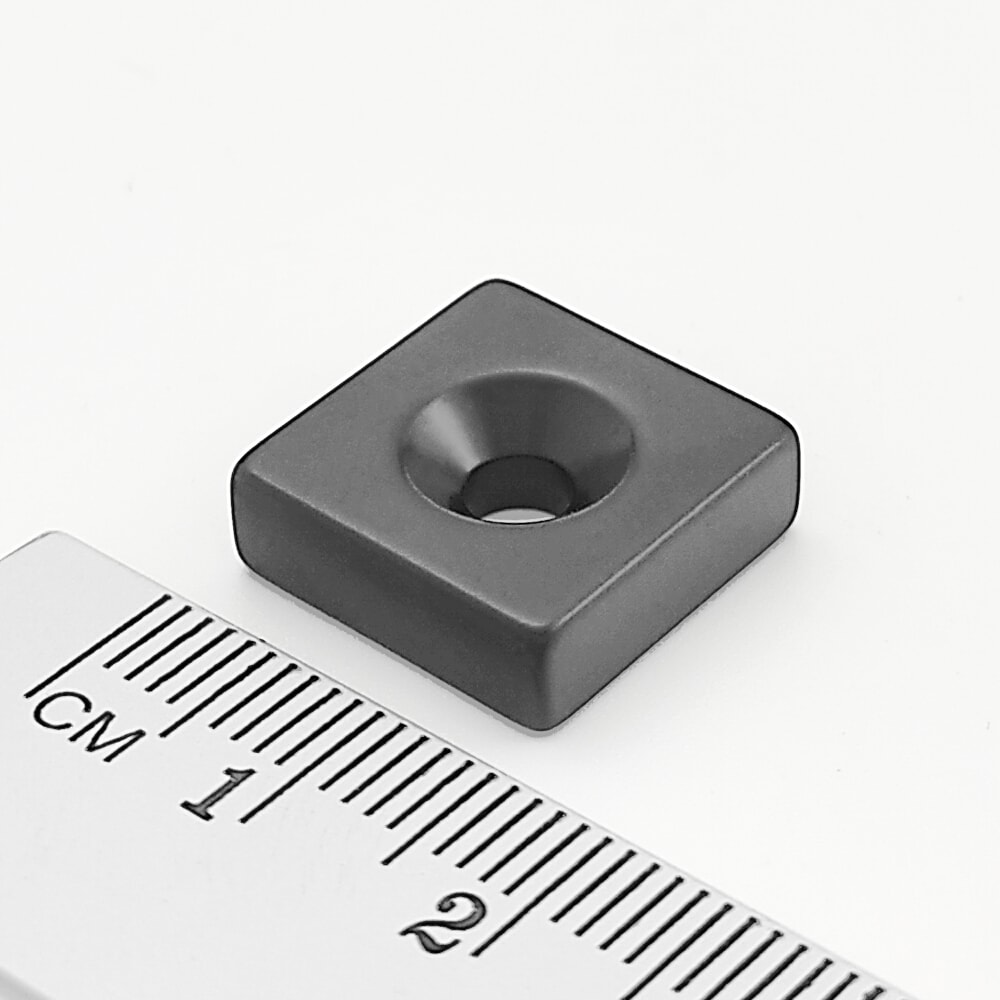

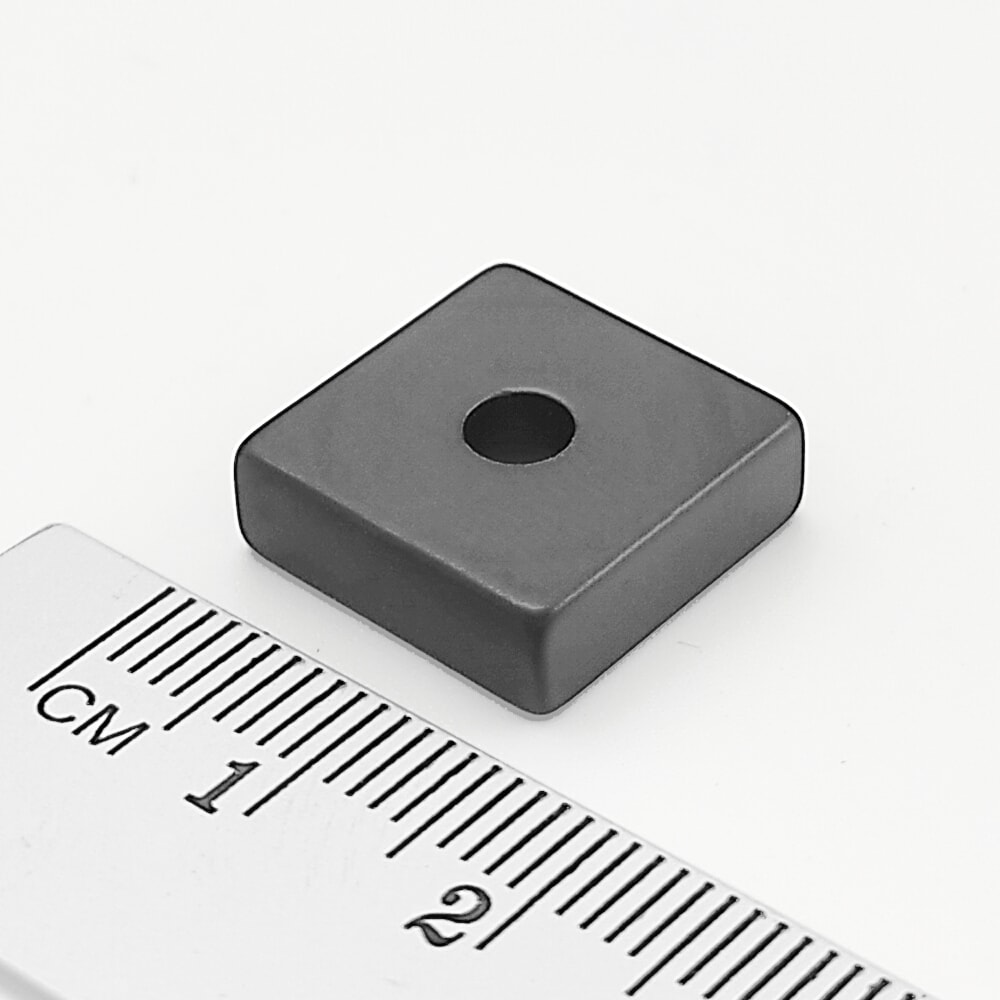

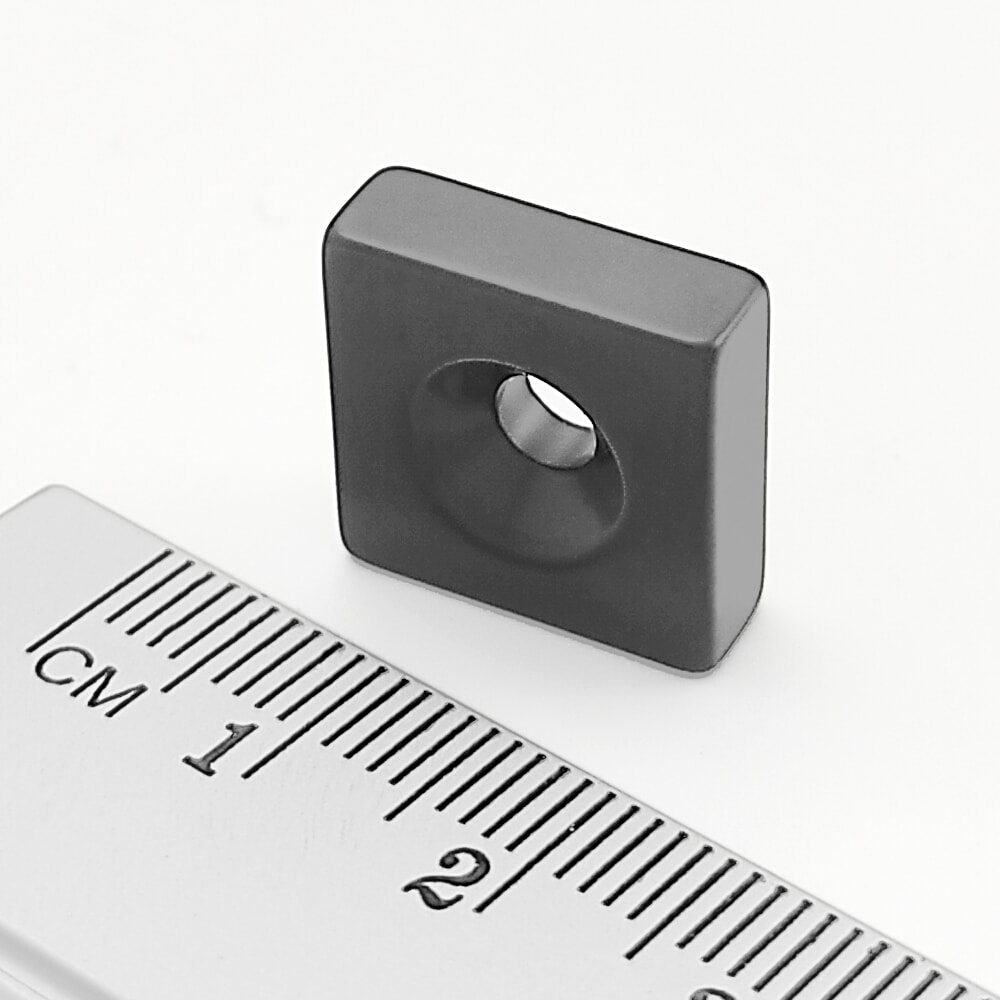

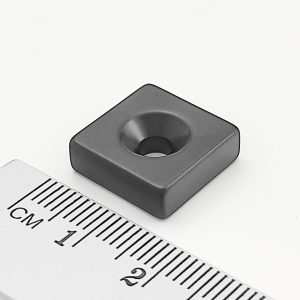

Neodymium magnet, block, 15×15×5 mm, with hole M4 (south pole on the countersunk side), epoxy – N42

1,89€ inc. Vat

The south pole is on the countersunk side as seen in the picture.

Quantity discounts

| From 1 pc: | 1,89€ |

| From 10 pcs: | 1,68€ |

| From 30 pcs: | 1,54€ |

| From 80 pcs: | 1,45€ |

| From 300 pcs: | Request a quote |

Properties

| Length | 15 mm |

|---|---|

| Width | 15 mm |

| Height | 5 mm |

| Hole size | M4 |

| Magnetic strength | 6,3 kg |

| Magnetisation direction | in the direction of thickness (shortest dimension) |

| Material | NdFeB – N42 (neodymium magnet) |

| Surface | four layers: nickel-copper-nickel-nickel-epoxy resin |

| Temperature resistance | up to 80 °C |

| Weight | 8,3 g |

Product description

The magnet is made of the world's strongest magnetic material NdFeB. This material is up to 10 times stronger than conventional ferrite magnets.

The table above shows the strength of the magnet. This is the force required to pull the magnet away from a thick steel surface under the following ideal conditions:

- The surface is made of pure steel and is at least half the thickness of the magnet itself.

- The magnet touches the surface with the entire surface.

- The magnet is pulled perpendicular to the surface (away from the surface).

- There is no gap between the magnet and the metal surface (e.g. paint coating).

In most cases, these conditions are not met and the strength tends to be several times lower. For more information, see the article What is the strength of a magnet in kg?

Brittleness

Although neodymium magnets look metallic, they are actually brittle and can break when hit:

If the magnets are going to be exposed to shocks, we recommend using our pot magnets instead of using this magnet. The steel pot is designed to protect the magnet from impacts.

Surface treatment

There are four layers of protection on the surface of the magnet: nickel, copper, nickel and epoxy resin. Epoxy resin is waterproof, so the magnet can be used outdoors or in humid environments.

Be careful with epoxy surface treatment. The polyepoxide layer can be easily scratched with a sharp object. The chemical resistance of the magnet is then lost and in the scratched place it starts to behave like a normal nickel treatment (our magnets still have a standard nickel protective layer under the polyepoxide) If the magnet is likely to be subjected to shock or severe scratching, we recommend using our rubber-coated magnets. Rubber-coated magnets are moisture resistant and their thick rubber coating will not scratch.

Drilling, sawing, welding...

Neodymium magnets are brittle, sensitive to high temperature and oxidize easily. The magnet may break when drilling or sawing with unsuitable tools. A magnet with a damaged surface finish may lose some of its strength over time. Therefore, we do not recommend mechanical processing of magnets. We can meet special requirements for the shape of magnets. For more information, visit Custom-made magnets.

High temperatures

Conventional neodymium magnets lose some of their strength when heated above 80 °C, and sometimes at lower temperatures. If you need a magnet with higher temperature resistance, see the category Magnets with high temperature resistance. The magnet is not affected by low temperatures.

Further information

For more information, see our FAQ page and our blog. You can calculate the pull-off force and magnetic field of any neodymium magnet with our magnetic calculator.

Do you need help?

Our magnet experts are available every working day. If you would like advice on your choice, please contact us at info@orodian.com or on +421 46 202 1200.