Physical properties of neodymium magnets

Neodymium magnets are made from a compound of neodymium, iron and boron Nd2Fe14B. This material is characterized by very high remanence and maximum energy product, which makes neodymium the strongest type of magnet in the world. At the same time, they are very resistant to demagnetisation by external magnetic fields.

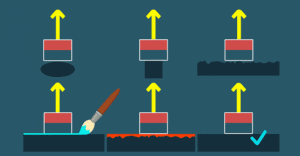

The weak aspect of neodymium magnets is low temperature resistance and fragility. The material Nd2Fe14B also chemically reacts with oxygen in the air, and therefore all magnets must be covered protective layer of chemically more stable material. It is usually nickel, zinc, epoxy resin, plastic or rubber.

In this article you will find an overview of the most important physical properties of neodymium magnets.

Temperature resistance

The neodymium magnet material can be described by the abbreviation NČČPP, where:

- N means it is a neodymium magnet

- ČČ is a two-digit number from 28 to 55. It represents the maximum energy product in MGOe units. The higher the number, the stronger the magnet.

- PP is a pair of letters that determines the heat resistance of the magnet.

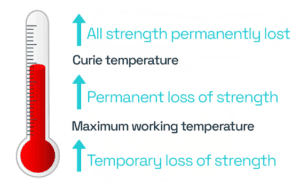

When a neodymium magnet is heated above its maximum working temperature, it begins to permanently lose magnetic strength. The more you heat it up, the more percentage of its power it loses. The Curie temperature is the temperature at which the magnet has no strength left.

Both the maximum working temperature and the Curie temperature depend on the PP suffix:

| PP suffix | Maximum working temperature | Curie temperature |

|---|---|---|

| without suffix |

80 °C |

310 °C |

| M | 100 °C | 320 °C |

| H | 120 °C | 320 – 350 °C |

| SH | 150 °C | 340 – 360 °C |

| UH | 180 °C | 350 – 380 °C |

| EH | 200 °C | 350 – 380 °C |

| AH | 240 °C | 350 – 380 °C |

The data in the table is only a rough estimate. Temperature resistance also depends on the shape of the magnet and its surroundings. More in the article about high and low temperatures.

Magnetic properties

The properties of the most commonly used materials are listed.

| Material | Remanence (Br) |

Coercive force (Hc) | Max. energy product (BH)max |

|||||

|---|---|---|---|---|---|---|---|---|

| Normal (Hcb) |

Internal (Hci) |

|||||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | |

| N30 | 1080-1130 | 10.8-11.3 | ≥796 | ≥10 | ≥955 | ≥12 | 233-247 | 28-31 |

| N33 | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥955 | ≥12 | 247-271 | 31-34 |

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 |

| N40 | 1250-1280 | 12.5-12.8 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 |

| N42 | 1280-1320 | 12.8-13.2 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 |

| N45 | 1320-1380 | 13.2-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 |

| N48 | 1380-1420 | 13.8-14.2 | ≥836 | ≥10.5 | ≥955 | ≥12 | 366-390 | 46-49 |

| N50 | 1400-1450 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 |

| N52 | 1430-1480 | 14.3-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 398-422 | 50-53 |

| N55 | 1450-1510 | 14.5-15.1 | ≥796 | ≥10.0 | ≥876 | ≥11 | 406-438 | 52-55 |

| M | ||||||||

| N30M | 1080-1130 | 10.8-11.3 | ≥796 | ≥10 | ≥1114 | ≥14 | 223-247 | 28-31 |

| N33M | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1114 | ≥14 | 247-263 | 31-33 |

| N35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 |

| N38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 |

| N40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 |

| N42M | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 |

| N45M | 1320-1380 | 13.2-13.8 | ≥955 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 |

| N48M | 1360-1430 | 13.6-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 |

| N50M | 1400-1450 | 14.0-14.5 | ≥1033 | ≥13.0 | ≥1114 | ≥14 | 382-406 | 48-51 |

| H | ||||||||

| N30H | 1080-1130 | 10.8-11.3 | ≥796 | ≥10.0 | ≥1353 | ≥17 | 223-247 | 28-31 |

| N33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 |

| N35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 |

| N38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 |

| N40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 |

| N42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 |

| N45H | 1320-1360 | 13.2-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 342-366 | 43-46 |

| N48H | 1370-1430 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 |

| SH | ||||||||

| N30SH | 1080-1130 | 10.8-11.3 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 |

| N33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 |

| N35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 |

| N38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 |

| N40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 |

| N42SH | 1280-1320 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 |

| N45SH | 1320-1380 | 13.2-13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 |

| UH | ||||||||

| N28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 |

| N30UH | 1080-1130 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 |

| N33UH | 1130-1170 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 |

| N35UH | 1180-1220 | 11.8-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 |

| N38UH | 1220-1250 | 12.2-12.5 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 287-310 | 36-39 |

| N40UH | 1250-1280 | 12.5-12.8 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 302-326 | 38-41 |

| EH | ||||||||

| N28EH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 |

| N30EH | 1080-1130 | 10.8-11.3 | ≥812 | ≥10.3 | ≥2388 | ≥30 | 223-247 | 28-31 |

| N33EH | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-271 | 31-34 |

| N35EH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 |

| N38EH | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 287-310 | 36-39 |

| AH | ||||||||

| N28AH | 1040-1090 | 10.4-10.9 | ≥787 | ≥9.9 | ≥2624 | ≥33 | 207-231 | 26-29 |

| N30AH | 1080-1130 | 10.8-11.3 | ≥819 | ≥10.3 | ≥2624 | ≥33 | 223-247 | 28-31 |

| N33AH | 1130-1170 | 11.3-11.7 | ≥843 | ≥10.6 | ≥2624 | ≥33 | 247-271 | 31-34 |

The table uses units of kilogauss (kGs), kilooersted (kOe) and megagauss-oersted (MGOe), as well as Tesla (T), kiloampere per metre (kA/m) or kilojoules per cubic metre (kA/m) – depending on which one(s) you need to use. The following relationships apply between these units:

- T = 10 kGs

- kA/m = 0.01257 KOe

- MGOe = 0.1257 kJ/m3

Mechanical and other properties

| Quantity | Value |

|---|---|

| Density | 7.4-7.5 g/cm3 |

| Thermal capacity | 350-500 J/(kg.°C) |

| Coefficient of thermal expansion in the magnetisation direction | 5.2 x 10-6 /°C |

| Coefficient of thermal expansion perpendicular to the magnetisation direction | -0.8 x 10-6 /°C |

| Compressive strength | 950 MPa |

| Tensile strength | 80 MPa |

| Vickers hardness test | 560-600 |

| Young’s modulus | 160 GPa |

Are you looking for a suitable magnet?

If you need advice on choosing a suitable magnet for your use, contact us at info@orodian.com or call +421 46 202 1200. We will help you choose a magnet from our offer or we can make custom magnets.