What is the strength of a magnet in kg?

In our e-shop with magnets, we list the breakaway force in kilograms for each magnet. In order to choose the right magnet for your purpose, it is important to understand what this number means.

The breakaway force is the force required to pull a magnet away from a thick steel surface under the following conditions:

- The magnet is pulled perpendicular to the surface.

- The magnet touches the surface with its entire surface.

- The surface is at least half the thickness of the magnet.

- The base is made of pure steel.

In most cases, these conditions are not achieved and therefore the strength of the magnet is lower. This article lists factors that can reduce the strength of a magnet.

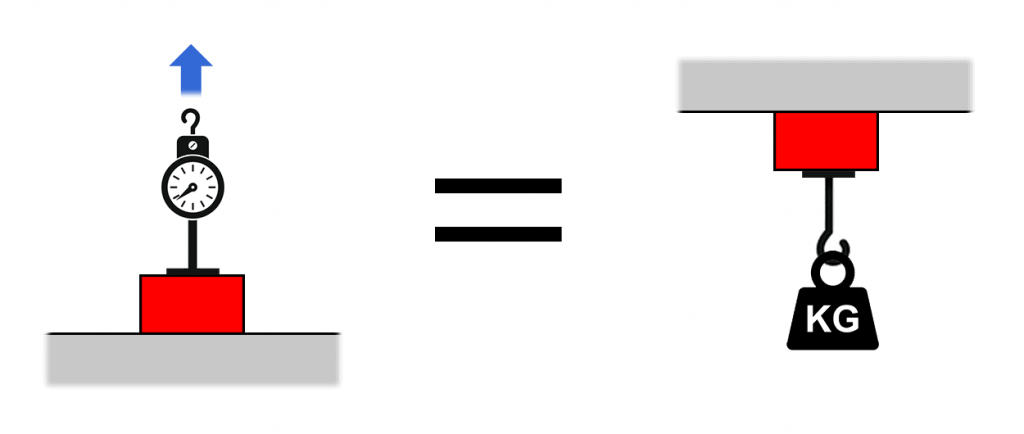

How do we measure breakaway force?

We place the magnet on a thick steel base, attach a load cell to it and increase the pulling force until the magnet breaks away from the base. The force at which the magnet breaks away is its breakaway force. We convert force from Newtons to kilograms using the relation 1 kg = 9.8 N.

The breakaway force in kilograms is also the maximum weight that the magnet can carry under ideal conditions:

What can reduce the strength of a magnet?

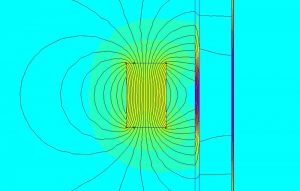

A gap exists between the magnet and the metal surface

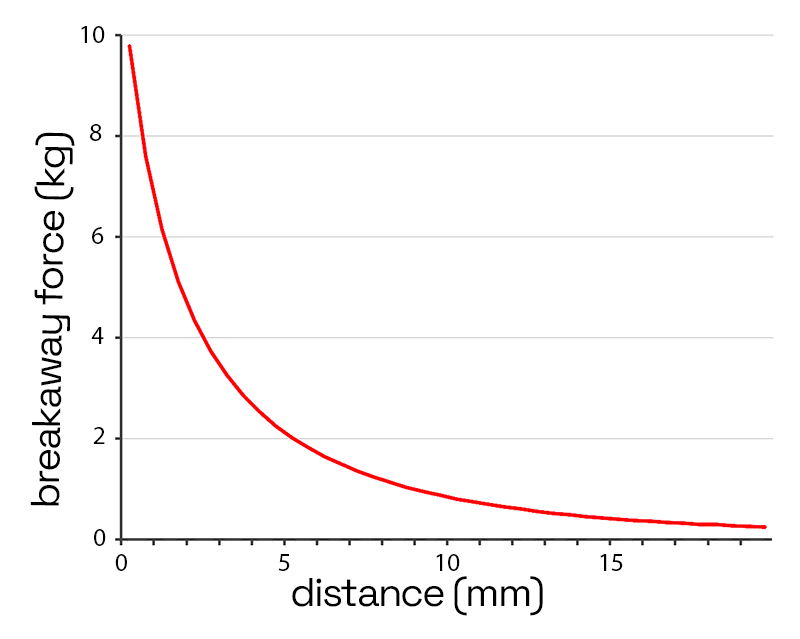

If there is an air gap or a layer of non-magnetic material (such as paint, plastic or rubber) between the metal surface and the magnet, the magnetic strength is reduced. The greater the distance between the magnet and the metal surface, the weaker the attraction. The power drops very sharply:

The graph shows the force of a neodymium magnet in the shape of a disc with a diameter of 20 mm and a height of 10 mm. Even with a gap of 2 mm, the strength of the magnet drops by half. At a distance of 10 mm, the magnet loses more than 90% of its strength.

The specific material between the magnet and the metal surface does not matter. It can be wood, plastic, paint, glass, air or other non-magnetic material. The magnetic strength depends only on the distance of the magnet from the metal surface.

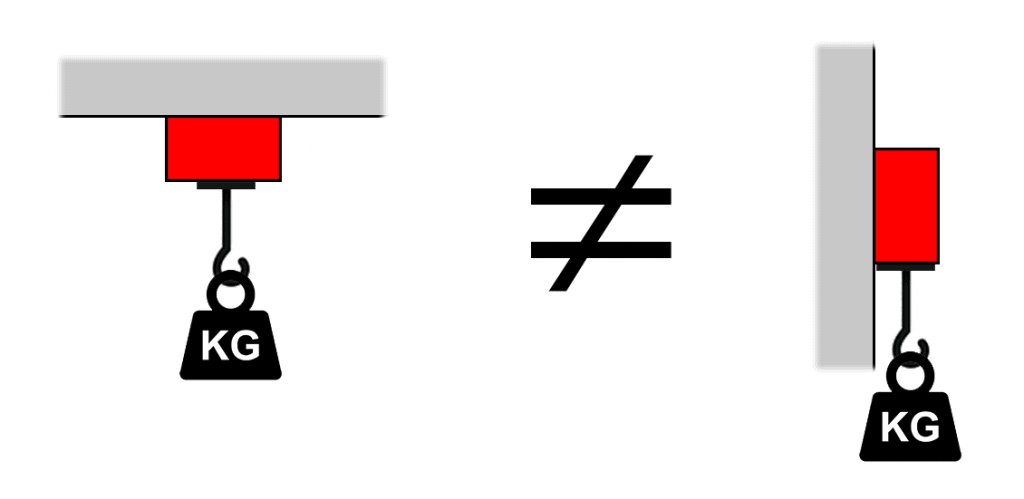

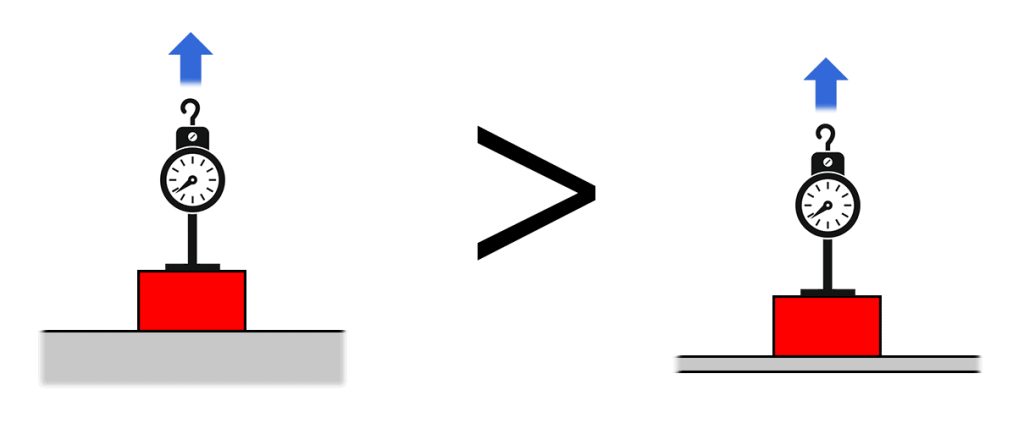

The magnet is not pulled perpendicular to the surface

In the second picture, the magnet is not pulled perpendicular to the surface, but laterally. A smaller force is usually required to slide the magnet than to pull it from the surface. How easily the magnet slides to the side depends not only on the strength of the magnet, but also on the friction between the magnet and the surface. The greater the friction, the more weight the magnet can carry without sliding. You can calculate the force required to slide the magnet as:

Force required for sliding = (breakaway force) x (coefficient of friction)

If the surface is smooth (for example, the paint on the refrigerator), the coefficient of friction is approximately 20%. This means that 5 times less force is needed to slide the magnet from the refrigerator than to pull it off!

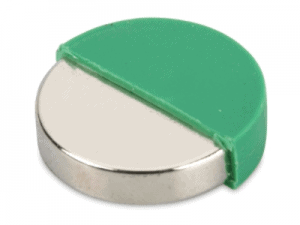

However, there are also materials (such as rubber) that have a coefficient of friction greater than 1. Such magnets are easier to pull off than slide across the surface. If you need to maximize the friction between the magnet and the surface, we recommend using rubber-coated magnets.

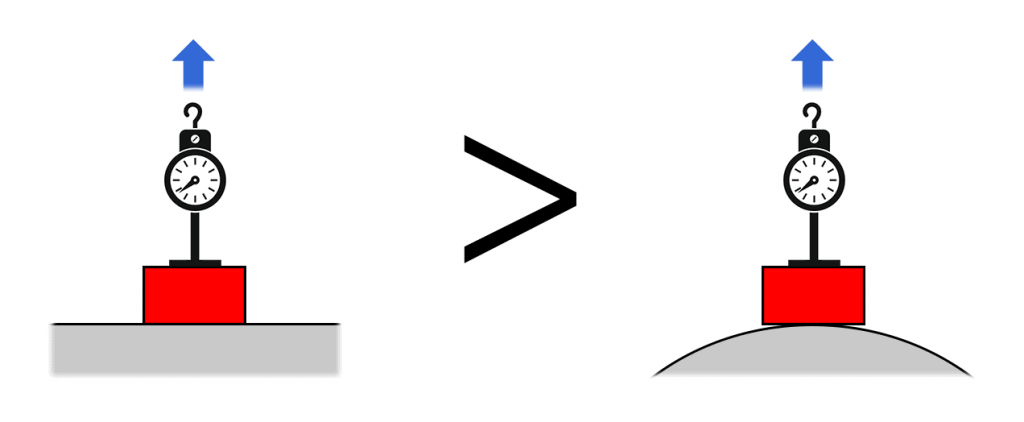

The magnet is not touching the surface with its entire surface

If the metal surface is uneven and the magnet does not touch it over the entire surface, the magnetic strength decreases similarly to the air gap.

The surface is not thick enough

In order to achieve the maximum force, the magnet must be placed on a sufficiently thick metal surface. If the surface has less thickness, the strength is reduced. However, this loss of strength becomes noticeable only with thin bases. For example, a 20×10 mm disc magnet achieves maximum force on sheet metal with a thickness of 5 mm or more. If we reduce the sheet thickness to 1 mm, the strength of the magnet drops to half. With a sheet thickness of 0.5 mm, the strength of the magnet drops to a quarter.

The surface is not pure steel

The breakaway force stated for our magnets was measured on a polished steel surface. If your surface is made of a different magnetic material (such as an alloy of iron with another metal) or the material is rusted, the strength may be lower. If almost all of the weight of the attracted object is iron, nickel or cobalt, the stated breakaway force should be about the same.

How strong a magnet do I need?

The strength-reducing factors described above mostly add up. For example, if you place a magnet on a refrigerator, you have to calculate that there will be a coating of paint between the magnet and the metal surface (decrease in strength by half), the magnet will slide on the surface (decrease in strength by 20%) and the thickness of the metal sheet will not be sufficient (decrease in strength by half). When these three factors are combined, the strength is reduced to 5-10% of the original strength.

Since the strength depends very much on the exact conditions, we recommend our customers:

- Order samples of several magnets and test them in practice.

- Factor in a margin and use a stronger magnet to be on the safe side.

- Try to minimize the factors described above (magnet sliding, air gap, surface unevenness, surface too thin, insufficiently magnetic material).

You can also call us at +421 46 202 1200 or write to info@orodian.com. We will be happy to advise you on your choice.