Can a neodymium magnet lose strength at high or low temperature?

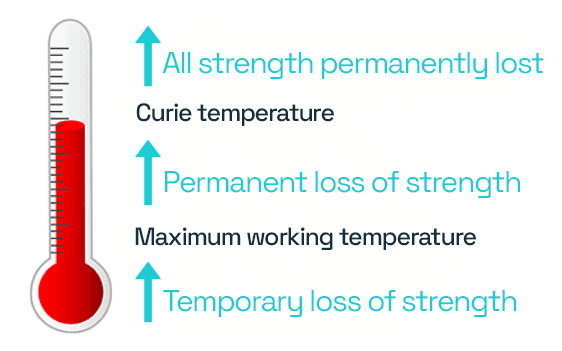

Heating a neodymium magnet always leads to a decrease in strength. However, there are two types of power loss:

- temporary loss of strength (after cooling down, the strength returns to its original value)

- permanent loss of strength

Temporary loss of strength

As long as the temperature of the magnet does not exceed the maximum working temperature, the magnet loses part of its strength only temporarily. After cooling to room temperature, its strength is fully restored again. In the case of a temporary loss of strength, the magnet usually loses 5-10% of its original strength at higher temperatures. How often the magnet is heated and cooled has no effect on the permanence of the loss f strength.

Permanent loss of strength

After exceeding the maximum working temperature, the magnet will remain weaker even after cooling. The higher the temperature a magnet reaches, the greater the permanent loss of its strength. Repeated heating to the same temperature will not cause a greater loss of strength. It doesn’t even matter how long the magnet has been heated.

After reaching the Curie temperature (approximately 300 °C), the magnet loses 100% of its strength.

Temperature resistance of NdFeB magnets

Not all neodymium magnets have the same temperature resistance. The maximum working temperature and Curie temperature are affected by:

- magnet material

- the shape of a magnet

- other magnets and magnetic metals in the vicinity

Material

The neodymium magnet material is usually marked with the abbreviation NČČPP (e.g. N38SH):

- N stands for neodymium magnet

- ČČ is a two-digit number from 25 to 55 and indicates the strength of the magnet. The higher the number, the stronger the magnet. (In scientific terms, it is the maximum energy product in MGOe units)

- At the end, there can be 1 or 2 two letters (PP), which indicate the temperature resistance of the magnet.

The table below reveals the maximum working and Curie temperature according to the letters at the end of the material:

| PP code | Maximum working temperature | Curie temperature |

|---|---|---|

| without suffix | 80 °C | 310 °C |

| M | 100 °C | 320 °C |

| H | 120 °C | 320 – 350 °C |

| SH | 150 °C | 340 – 360 °C |

| UH | 180 °C | 350 – 380 °C |

| EH | 200 °C | 350 – 380 °C |

| AH | 240 °C | 350 – 380 °C |

However, the temperatures in this table are only approximate, and the actual values may be different for specific magnets – and even significantly so. The final temperature resistance of a magnet depends to a large extent on its shape and surroundings.

Shape of magnet

Even if the magnets are made of the same material, different dimensions can cause different temperature resistance. Thick magnets withstand high temperatures better than thinner ones. The temperatures given in the previous table are accurate for magnets in the shape of a disc, whose diameter is about 4 times larger than its height. The effect of dimensions on the temperature resistance of the magnet can also be seen in the following table:

| Magnet | Material | The standard max. working temperature | Actual max. working temperature |

|---|---|---|---|

| Disc 10×1 mm | N38 | 80 °C | appr. 60 °C |

| Disc, 10×2 mm | N38 | 80 °C | appr. 80 °C |

| Disc, 10×3 mm | N38 | 80 °C | appr. 100 °C |

| Disc, 10×5 mm | N38 | 80 °C | appr. 120 °C |

| Disc, 10×10 mm | N38 | 80 °C | appr. 140 °C |

Block or ring magnets behave similarly. The size of the magnet is not important for the heat resistance of the magnet; only the ratio of its dimensions matters. rods 5×5, 10×10 and 20×20 therefore have the same maximum working and Curie temperature.

“Stronger” materials with a higher ČČ number are more susceptible to loss of strength at lower temperatures than those with a lower ČČ number:

| Magnet | Material | The standard max. working temperature | Actual max. working temperature |

|---|---|---|---|

| Disc, 10×3 mm | N38 | 80 °C | appr. 100 °C |

| Disc, 10×3 mm | N42 | 80 °C | appr. 80 °C |

| Disc, 10×3 mm | N52 | 65 °C | appr. 60 °C |

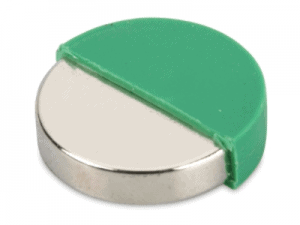

Discs magnetised diametrically (poles are on the sides, not on the flat sides) often have low temperature resistance. If they are to be exposed to high temperatures, we recommend testing them before use.

Around the magnet

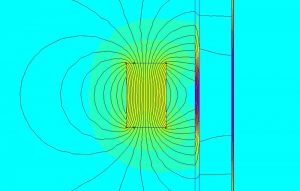

All previous calculations assume that there are no other magnets or magnetic metals near the magnet.

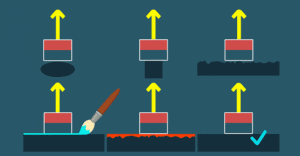

If a magnet is exposed to an opposite magnetic field (it is repelled by another magnet), it loses its strength even at lower temperatures. On the contrary, if the external magnetic field has the same direction as the magnet’s field (for example, it is placed on another magnet), its temperature resistance increases.

If the magnet is stuck to steel or other ferromagnetic material, its max. working temperature will decrease slightly.

Low temperatures

The lower the temperature, the stronger the neodymium magnet. This also applies to very low temperatures down to -130 °C. When cooled below -130 °C, the magnet begins to lose its strength. After warming up to room temperature, the strength returns to its original value. With a rapid increase in temperature, the magnet may break due to uneven thermal expansion. Neodymium magnets can be cooled with liquid nitrogen without damage. Reheating and cooling the magnet does not affect its strength until the maximum working temperature is exceeded.

Do you need magnets with high heat resistance?

If you plan to expose the magnets to a temperature higher than 80 °C, you have several options:

- Use ordinary neodymium magnets, which lose a fraction of their strength due to heating. However, they retain some of their strength unless you heat them to the Curie temperature of 300 °C.

- Use special neodymium magnets with high temperature resistance. We can custom-make such magnets for you.

- Use a different type of magnet instead of neodymium magnets. For example, ferrite magnets that have a temperature resistance of up to 250 °C are suitable.

You can find our offer of heat-resistant magnets in the category magnets with high temperature resistance. You can also choose from the following list of best-selling magnets with a high maximum working temperature: